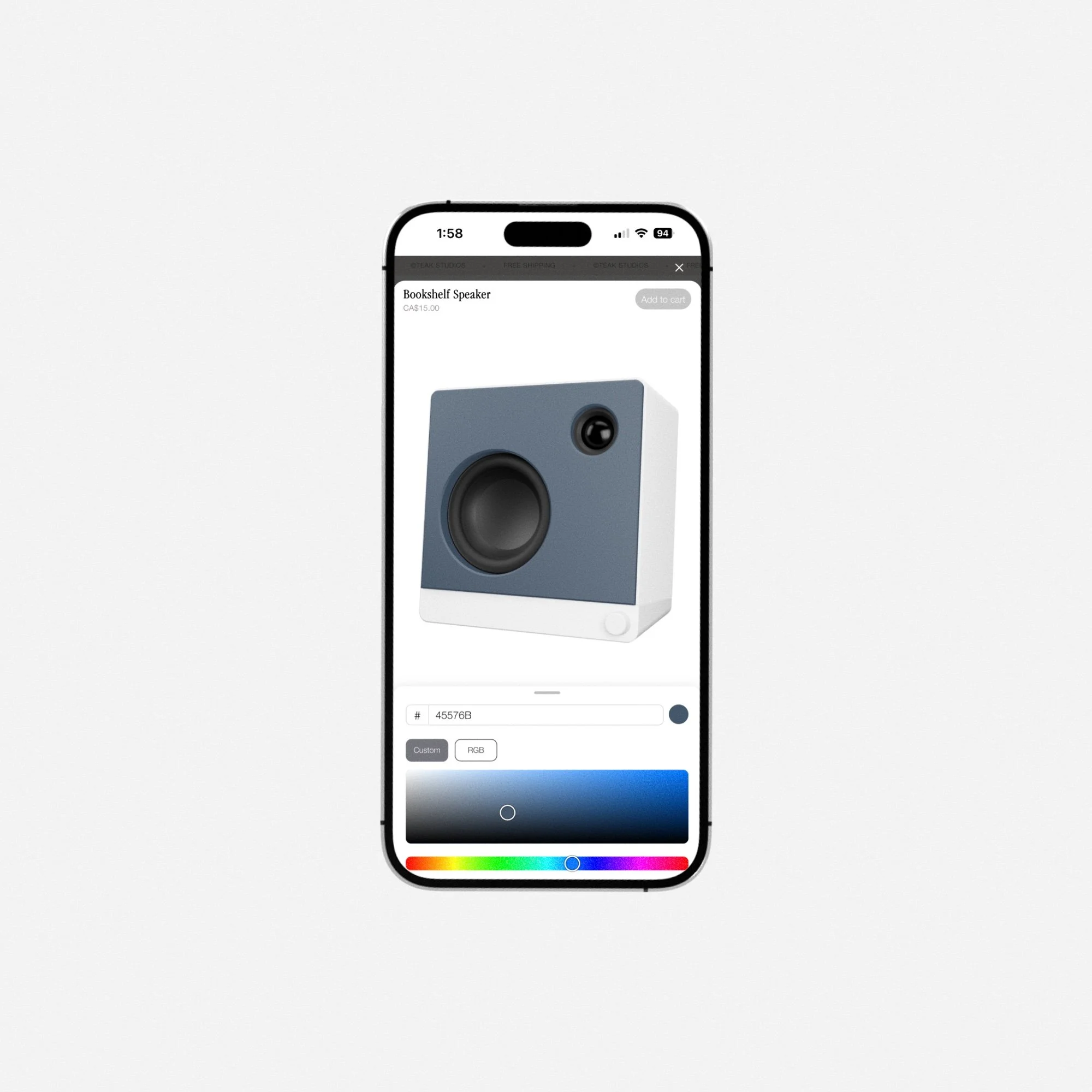

3D print customization interface

2025

This project focused on enabling deep customization for a highly parametric 3D printed product with many interdependent options. Because variations such as different styles, corners, and covers are essentially free with 3D printing, a single part can quickly expand into dozens of files, making it difficult to select the correct configuration without a GUI.

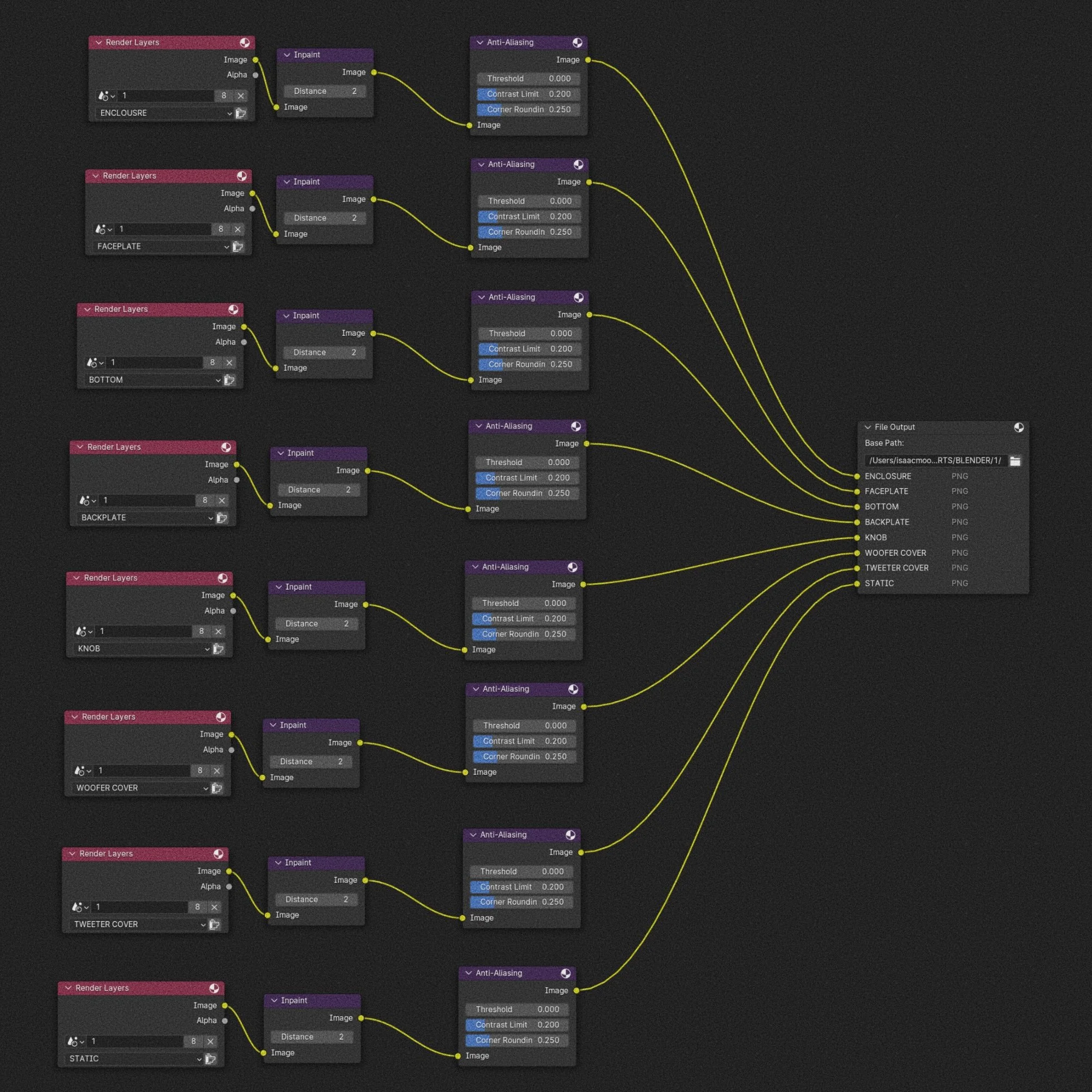

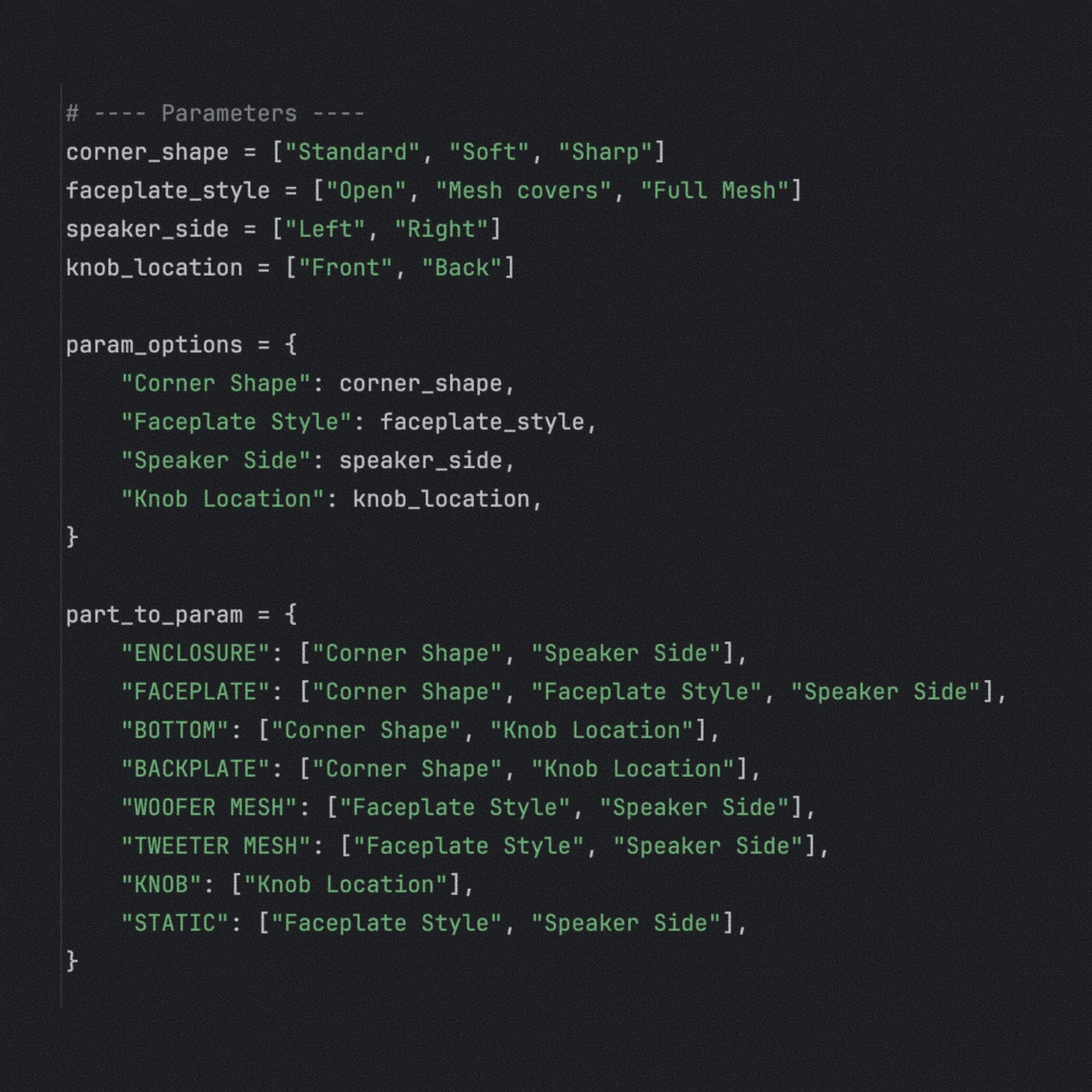

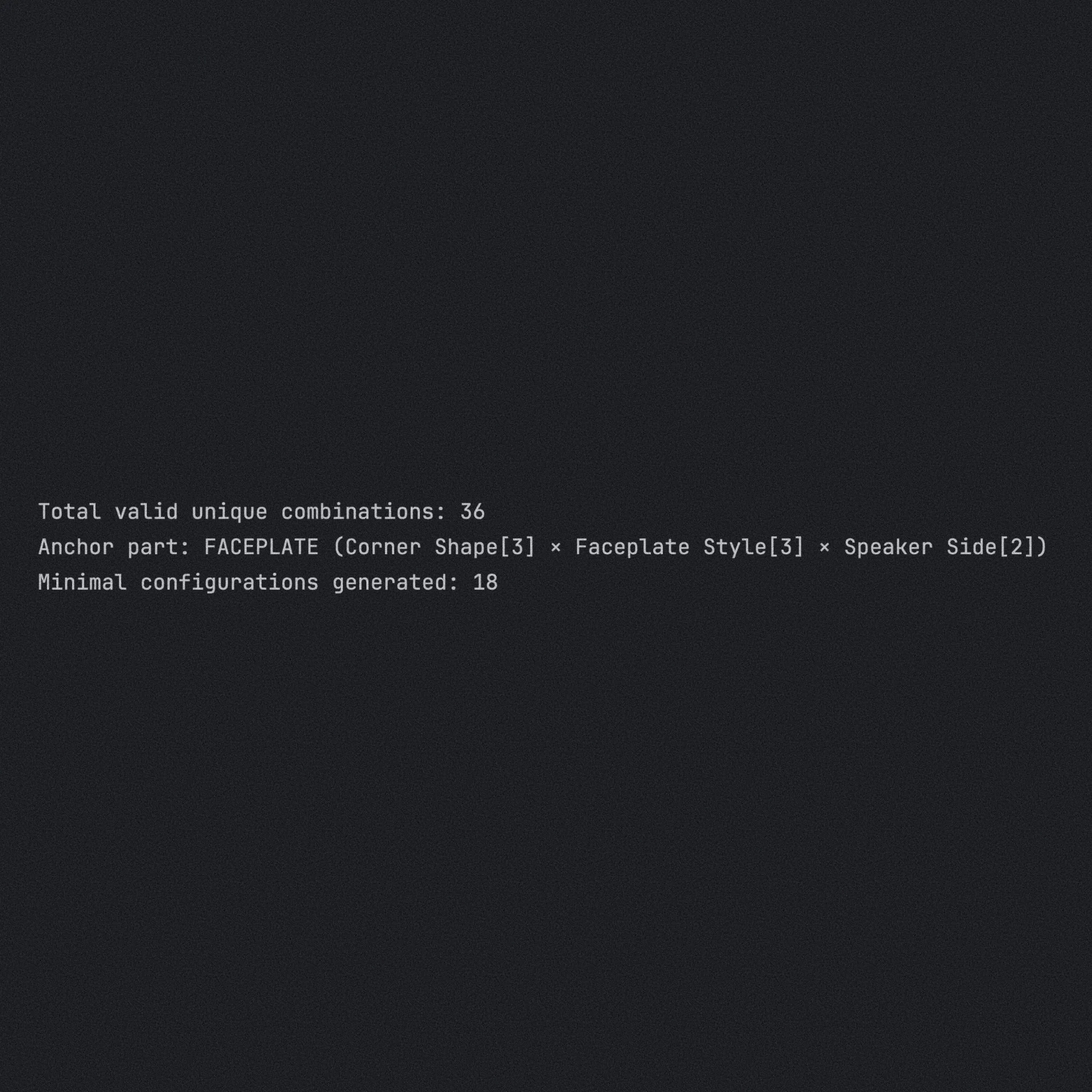

I designed the product as a fully parametric CAD model in Onshape and used Python to determine the minimum set of valid configurations and automate STL exports and the Blender rendering pipeline. These renders were integrated into the Kickflip product customizer, keeping frontend logic extremely clean for the end user, while sorting through the complexity of different file variations with backend logic.

Select the color of each individual part

Select the variation you want. For example the grille style shown here

Secondary view of the back

Blender compositing to render each individual part as its own layer. Inpaint and anti-aliasing nodes are used to reduce artifacts when layering the images

Defining the parameters in python that are then used to generate the configurations and logic statements

Summary of the output of the python script. 36 total unique combinations of the product are possible